Robotic Aluminium Spot Welding

The most robust welding solution for AL Resistance Spot Welding !

Aluminium Resistance Spot Welding

Several different types of alloys are used, mainly from the 5xxx (5182, 5774, etc…) and 6xxx series (6014, 6016, 6111, etc…).

Depending on the applications, they can take the form of sheets, mold castings, HPDC (high pressure die casting) or extruded parts. They are used in most BIW areas; underbody, body side, framing, closures and battery casing. Various thicknesses , grades are mixed and combined, without or in most cases with structural adhesive, whose use is fast growing to enhance the rigidity of assemblies.

High welding current is necessary to weld aluminium alloys due to their high level of electrical conductivity, A very short welding time (60 to 250 ms) is required . The use of force profile ensure the best weld quality (force increase during squeeze and forging).

State of the Art detailed in clear Welding Guidelines

The guidelines are established to support at early stage of the project. It describes how to implement RSW to parts design, how to determine robust welds : defines weld parameters (welding current combined to force profiles), weld stength, type and size of equipment required. In some case additionnal information can be provided, due to specific condition of parts configuration, pairing thicknesses distibution, structural adhesive or any other customized situation : our welding lab experts can support with trials and expertise.

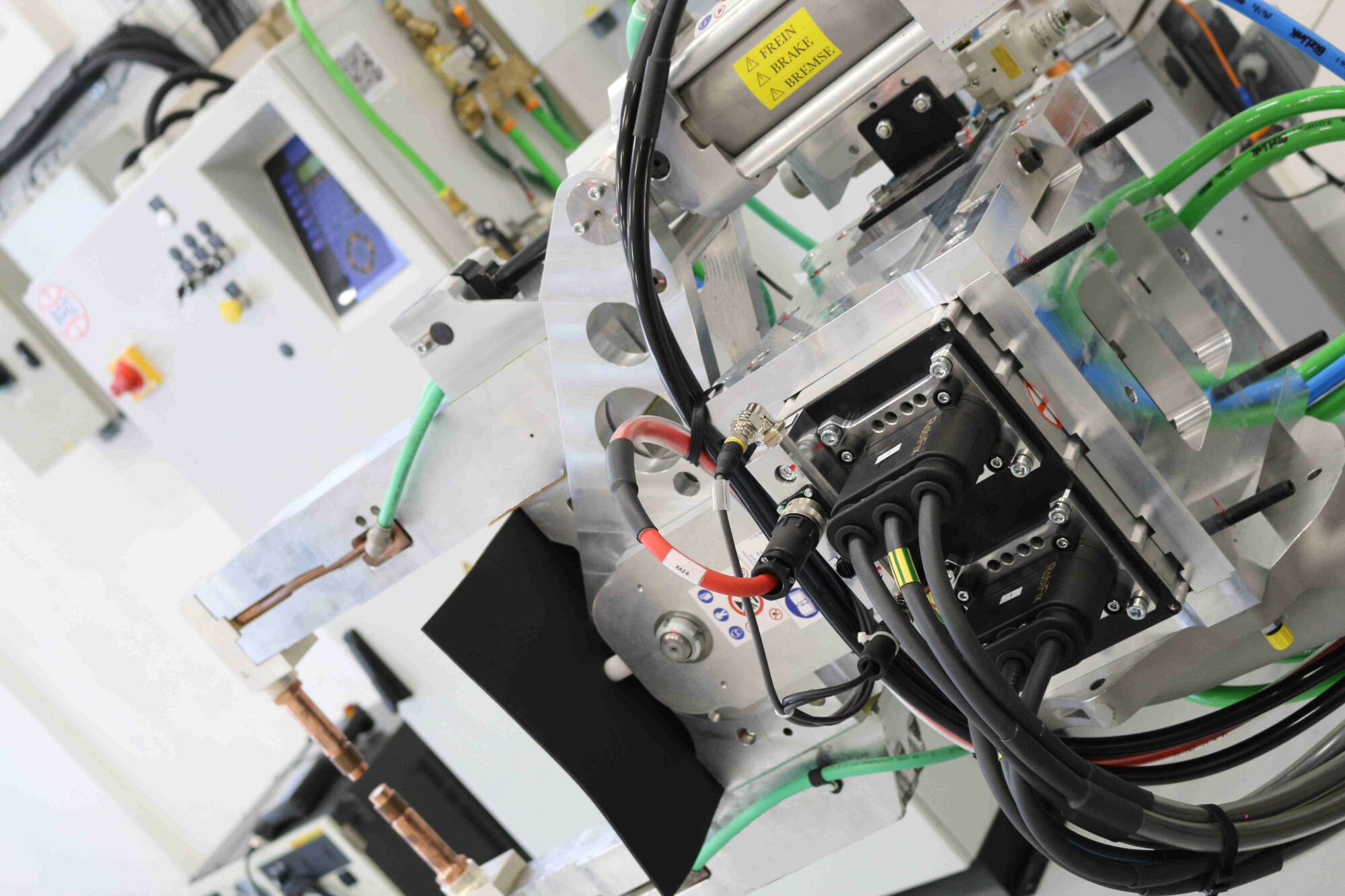

Combining Weld Gun and Controller

Competitive complete work stations, covering part combinations ranges from thin to thick aluminium materials. Full compatibility, Clear and documented behaviour.

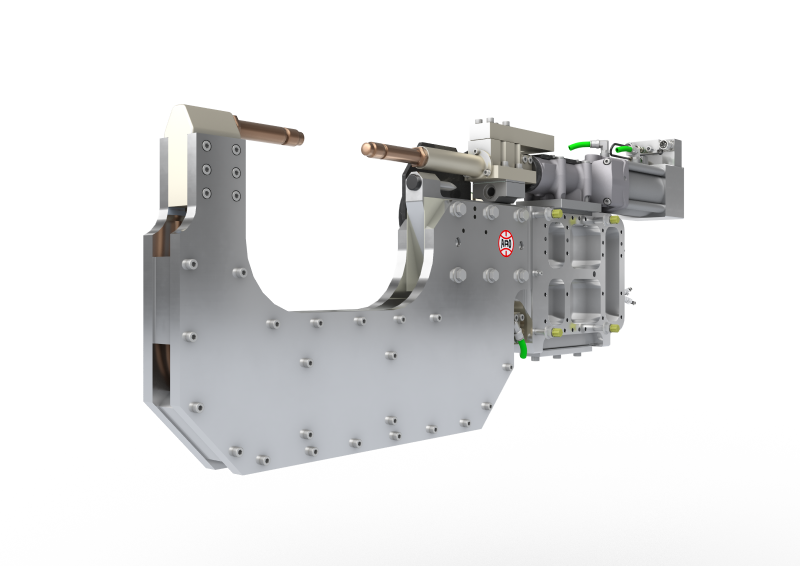

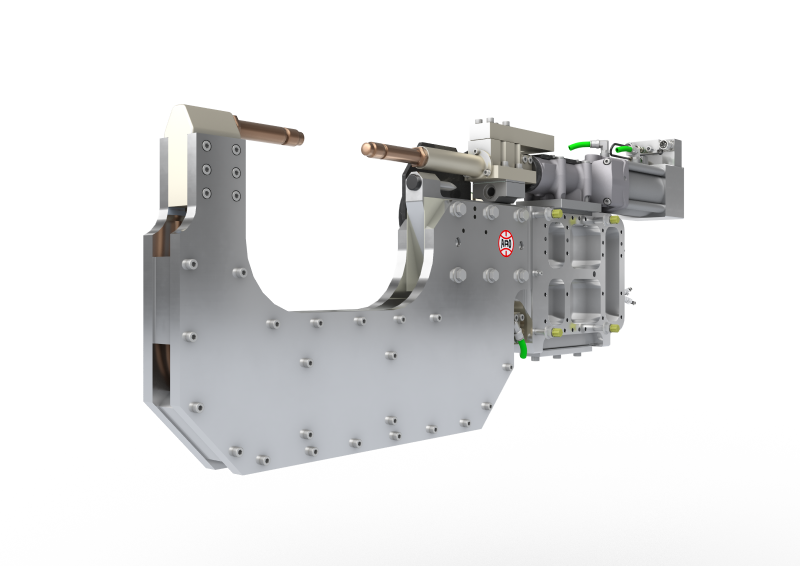

- Welding guns – stiff design – servo with force sensor and brake

- IBox controller driving the weld gun : forcel profiles – centralize management of all welding data and parameters.

High reliability & guaranteed performance and compatible with any robot. The full package can include the Robot F-Package, dresser and caps changer.

Weld Gun & Controller packages

| Weld Gun Type | R3D | RCH | RWH | RHH-RHG |

|---|---|---|---|---|

| Frame | C | C | X | X |

| Force sensor | yes | yes | yes | yes |

| Design force | 8kN | 12kN | 12kN | 12kN |

| Controller Type | iBox 800 | iBox 1200 | iBox 1200 | iBox 1200-2400 |

| Design Current | 35kA | 55kA | 55kA | 55kA-65kA |

| Adaptive mode | Option | Option | Option | Option |

Our Products

HD Robotic Welding Guns

Controls & Software

ARO offers a large range of integrated welding controllers equipped with the latest technology of welding controls. From the standard AC-MFDC cabinets to the advanced concept cabinets (auto-adaptive).

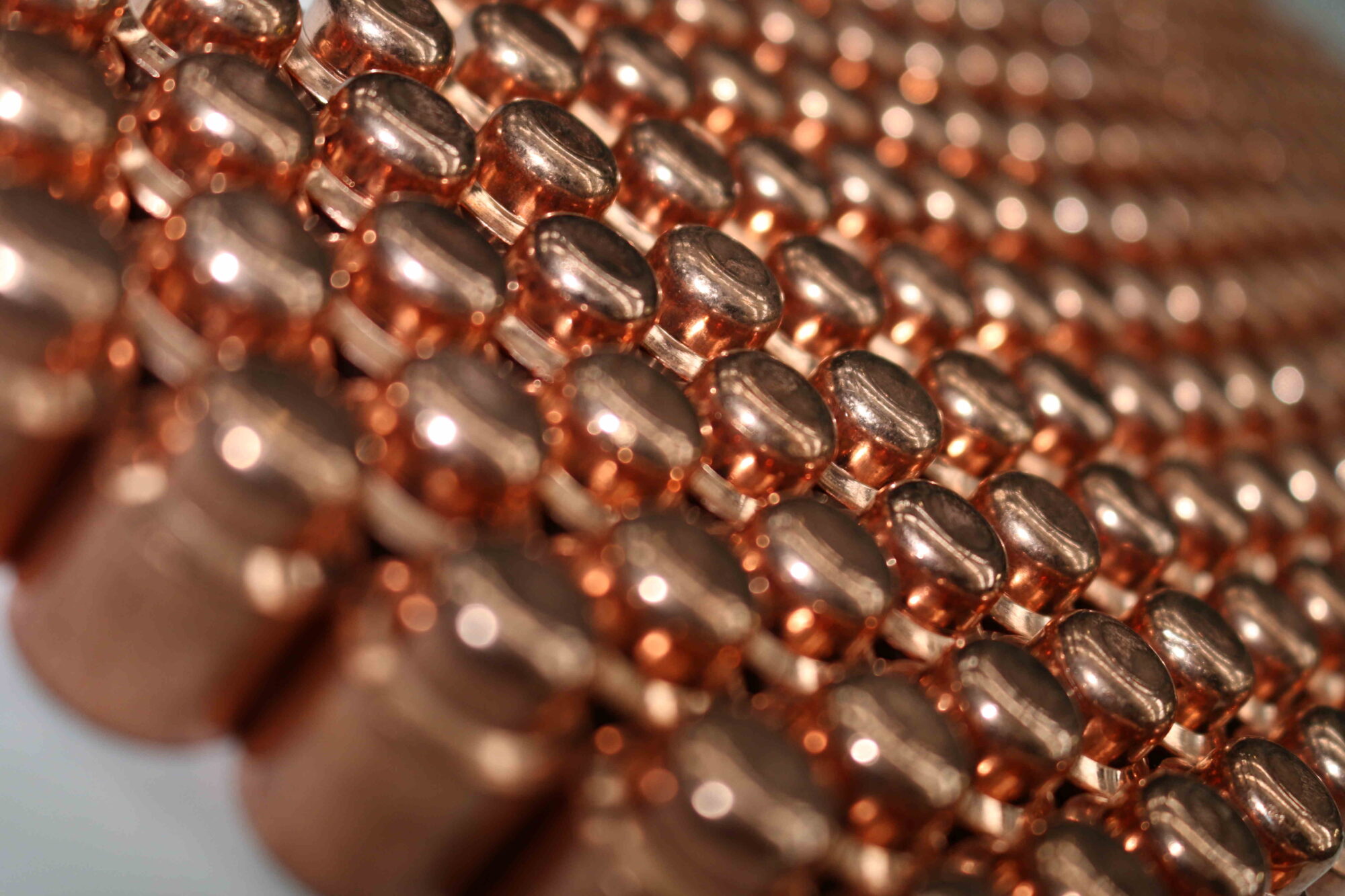

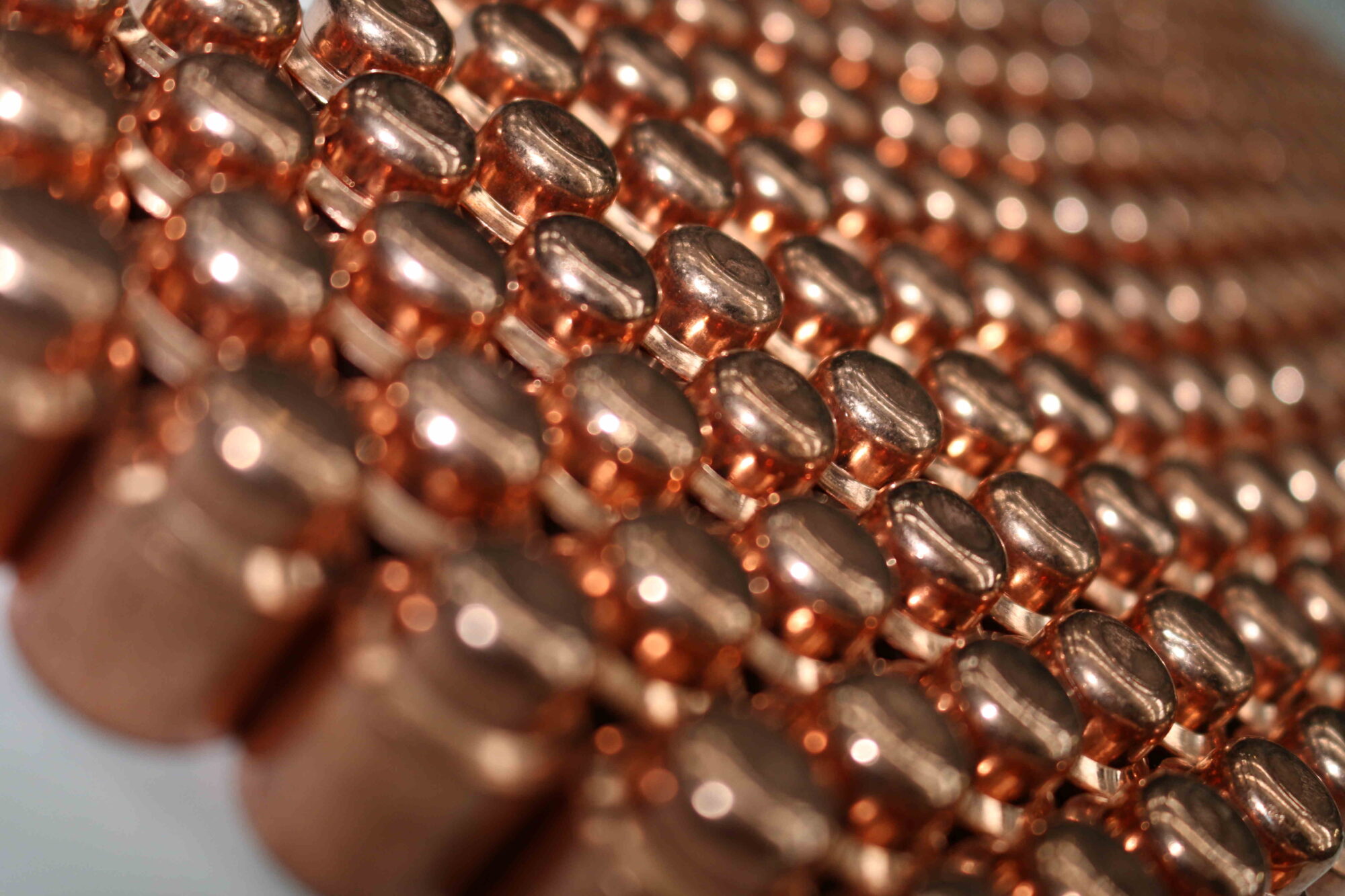

Welding Consumables

ARO offers a diverse range of electrodes for all welding applications. Different shapes and materials to perform high quality welds even under most severe conditions. ARO also offers a wide range of straight and bent cap adaptors, designs and manufactures specific parts upon request.

Welding Peripherals

A large range of accessories and peripherals, reliable and high performance, they become the elements that you cannot do without when implementing global welding solutions.

Welding Components

ARO designs and manufactures its own range of transformers, Servo motors and electronic controls because they are essential components of the resistance welding process.