MOS series

MOS series is the heavy duty range of stationary machines

ARO offers a heavy duty range of stationary welding machines integrating the latest technologies of servo actuator with embedded force sensor driven by iBox controller. Originally designed and qualified for aerospace industry standards, these machines can deliver high welding currents and welding forces with a complete control over all resistance welding parameters

MOS II AERO Qualified for Aerospace industry standards

Includes:

- Servo and MFDC technology

- Force profiles; Current control

- Traceability of all measurements / data recording of each weld.

Machine compliant with the Aerospace related standards and qualified for Aluminium / Titanium / Stainless steel grades.

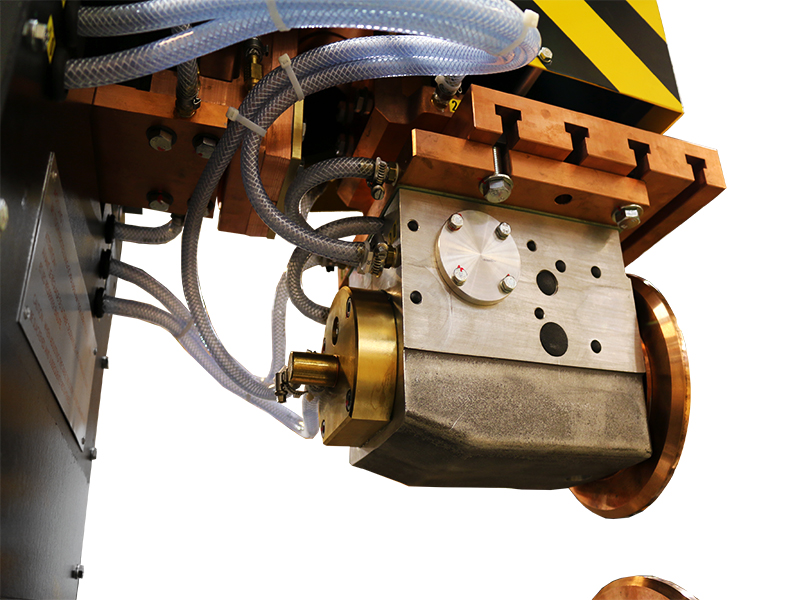

Seam Welding

the MOS II & III machine provide a large range of configurations for seam welding applications :

- Seam wheel movement driven by single or double servo-actuator

- seam wheels available in various sizes/diameters

- Flexibility of seam orientation/configuration

MOS series

- Application : Spot

- Technology : MFDC – AC

- Actuator : Pneumatic

- Design Current : 55kA -66kA

- Design Force : 24kN

- Application : Spot

- Technology : MFDC – AC

- Actuator : Pneumatic

- Design Current : 100kA -100kA

- Design Force : 24k

- Application : Spot

- Technology : MFDC

- Actuator : Servo

- Design Current : 55kA

- Design Force : 20kN

- Application : Projection

- Technology : MFDC – AC

- Actuator : Pneumatic

- Design Current : 55kA -65kA

- Design Force : 29kN/54kN

- Application : Projection

- Technology : MFDC – AC

- Actuator : Pneumatic

- Design Current : 100kA -100kA

- Design Force : 2.9kN/54kN

- Application : Projection

- Technology : MFDC – AC

- Actuator : Servo

- Design Current : 55kA -65kA

- Design Force : 20kN

- Application : Projection

- Technology : MFDC – AC

- Actuator : Servo

- Design Current : 100kA -100kA

- Design Force : 20kN

- Application : Seam

- Technology : AC

- Actuator : Pneumatic

- Design Current : 23kA

- Design Force : 10kN

- Application : Seam

- Technology : AC

- Actuator : Pneumatic

- Design Current : 23kA

- Design Force : 15kN

ARO Controls & Software

Essential to the efficiency and reliability of any welding process is the control system. ARO offers its own range of controls, transformers, power cabinets and dedicated welding sequence and cabinet monitoring software designed to perfectly complement ARO’s legendarily reliable welding heads. Allied to ARO’s extensive range of welding guns, this combination of power and process control, ensures that ARO resistance welding products deliver in each and every demanding situation.